| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : YT

Model Number : EX60-5

Place of Origin : China (Mainland)

MOQ : 1PCS

Price : Negotiable

Payment Terms : L/C,T/T

Supply Ability : 10000 PCS/Month

Delivery Time : 5-30Days

Packaging Details : Standard Export Packaging

Origin : Fujian, China

Material : 50Mn

Technique : Forging/Casting

Trademark : OEM

Model NO. : EX60-5

Certification : CE, ISO9001: 2000

Warranty Time : 1 Year

Surface Hardness : HRC50-56

This highly precise engineering surpasses simple basic compatibility, achieving unparalleled performance through the rigorous adherence to stringent manufacturing tolerances. Each track roller undergoes meticulous machining processes, guaranteeing consistent diameters and flawlessly smooth surfaces. As a result, these components excel in minimizing operational friction, achieving a remarkable 30% reduction when compared to standard replacement parts. This substantial improvement in friction reduction significantly boosts overall operational efficiency, setting new standards in performance and reliability.

Direct factory purchases guarantee rigorous quality control. Our advanced manufacturing facilities and highly skilled technicians monitor every stage, from sourcing raw materials to production. Final inspections ensure top-quality track rollers reach customers. Buy from us for the best.

Direct factory purchases guarantee rigorous quality control. Our advanced manufacturing facilities and highly skilled technicians monitor every stage, from sourcing raw materials to production. Final inspections ensure top-quality track rollers reach customers. Buy from us for the best.

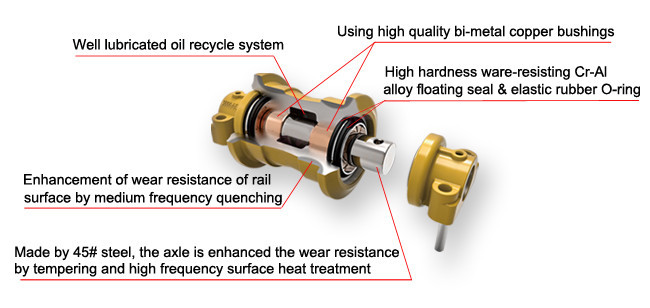

5. Track Roller Structure

6. Design/Structure/Main Dimensions of Installation

7. Our Advantages

* World-class quality

* Factory sale directly with reasonable price

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* After-sale services: video technical support,24h online support

8. Hot Sale Products

|

|

EX60-5 Undercarriage Rollers Forged Billet Core Forging / Casting Technique Images |